Sustainability has become the buzzword these days as the customers are getting increasingly eco-sensitive and regulatory environments are becoming stricter and the mattress industry. In lieu of this, the mattress manufacturers across the globe are compelled to rethink how they source, manufacture and dispose of their products. Since the beginning, mattresses have been produced with polyurethane foam, polyester materials and synthetic glues, most of which are based on fossil fuels and contribute heavily to landfill waste and ecological degradation. Now, with the growing awareness about environment, customers are demanding mattresses that do not harm the environment as well as humans and this is leading to manufacturers developing and using organic methods and material for making mattresses.

Today, a new generation of eco-friendly mattress options, including bamboo fabrics, natural latex, organic cotton and plant-based foams that offer high-performance comfort with a lower environmental impact are emerging extensively. Here, it is to be noted that sustainability does not mean considering only the product, but the entire production model i.e., from raw material sourcing to end-of-life management, and hence, mattress manufacturers in India as well as abroad are taking into account this as well.

Growing preference for sustainable and eco-friendly materials globally

When it comes to eco-friendly materials, then the global consumers seem to be more interested in them. In particular, the trend is observed in the U.S. and Europe, where government action also firmly supports the sustainability requirements. In fact, in Europe, Ecolabel-certified mattresses have observed double-digit growth in Germany, the Netherlands and Sweden. In the U.S., certifications like Global Organic Textile Standard (GOTS), CertiPUR-US® and GREENGUARD are now increasingly driving demand among environmentally responsible buyers. That said, global companies such as Avocado Green Mattress (USA) using certified latex, GOTS-certified organic wool and cotton, Saatva (USA) offering a latex hybrid made with organic materials and recyclable coils, Hästens (Sweden) offering handcrafted mattresses with horsehair, cotton and wool, Kipli (France) using 100 per cent natural latex and Tencel covers and Emma Sleep (Germany) developing modular, circular designs with recyclable foams among others are capturing the major market share by defining themselves as sustainability leaders.

Although the US and the EU are at the forefront, India’s mattress industry is also catching up on this front. As per the Mintel Global Outlook on Sustainability report for 2024, “68 per cent of urban Indian shoppers emphasised on environmental friendly qualities when buying mattresses, which was up from 49 per cent in 2021.”

Many brands in the country are now designing mattresses using eco-friendly materials and advanced technologies to ensure quality sleep.

Thus, the Indian brands too are reacting to this customer demand by utilising materials which are organic, biodegradable and devoid of any chemicals during mattress manufacturing. Additionally, the concept of circular economy is also gaining popularity in the nation with many brands providing mattress recycling options and take-back initiatives to reduce the landfill disposal.

Eco-friendly mattress material options popular worldwide

Environmentally friendly mattress materials not only conserve the planet but provide quality sleeping experience as well. So, let’s explore the most effective options being explored worldwide.

- Bamboo and Tencel fabrics: Made from renewable cellulose sources, they are naturally hypoallergenic, breathable and biodegradable. They require less water and fewer pesticides as compared to cotton. They are ideal for mattress covers and ticking.

- Organic cotton and wool: They are certified by standards like GOTS and OEKO-TEX and are free from harmful chemicals and provide excellent temperature regulation and comfort. Organic cotton is breathable, chemical-free and skin-friendly and is used for mattress covers and quilting. Wool also offers flame resistance without synthetic additives.

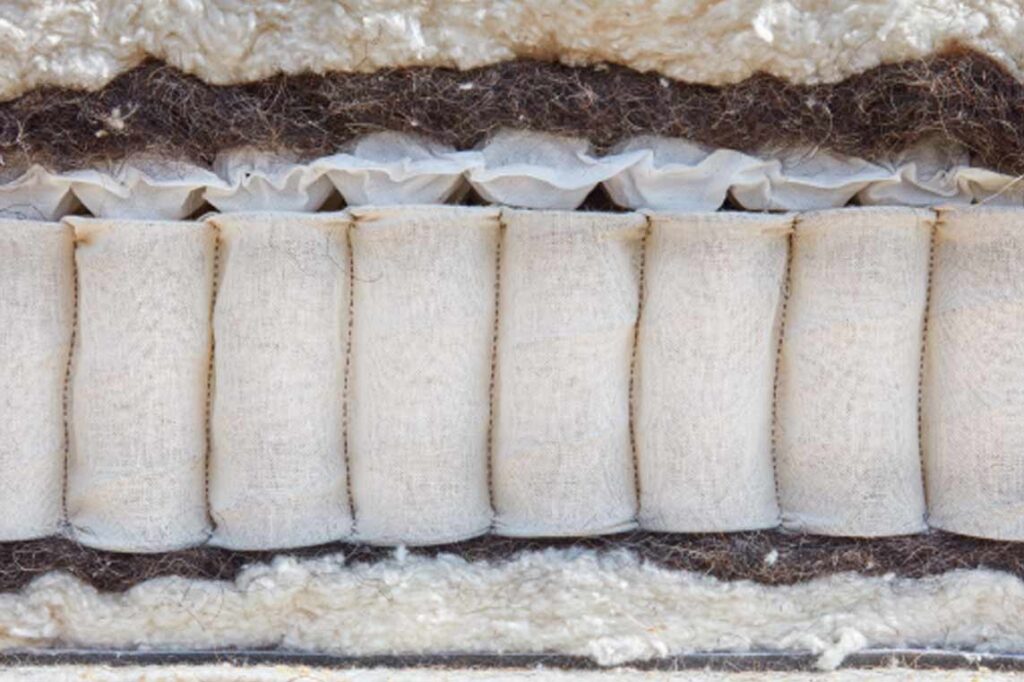

- Natural latex: It is sourced from rubber tree sap. Biodegradable and naturally hypoallergenic, it offers excellent support, breathability and pressure relief. As per Research Nester, 2023, “Natural latex consumption in the mattress industry is expected to reach $1.5 billion by 2030, growing at a CAGR of 7.1 per cent.”

- Plant-based memory foam: It is made partially from soy, castor or coconut oil. It reduces the use of petroleum-derived polyurethane and performs similarly like conventional memory foam but with a lower carbon footprint. It is used to make support/comfort layers. According to IBISWorld 2024, “Plant-based foams make up 6–8 per cent of global foam sales in sleep products, but adoption is expected to rise as regulations on petrochemical content tighten.”

Eco-friendly mattress materials in India

After going through the eco-friendly materials popular worldwide, let’s take a look at some of the popular options in India as well.

- Coir (Coconut Fiber): Coir has been the backbone of India’s natural mattress segment for decades. Mayank Sharma, Business Head – Hospitality, Premium Segment, King Koil-India, says, “The eco-friendly mattress material market is picking up fast in the country and one of the most eco-friendly materials is Coir. Derived from coconuts’ husk, this product is easily available throughout South India, notably in Kerala, Tamil Nadu and Karnataka. Coir is largely utilised in mid-segment mattress models, either individually or integrated with PU foam layers, since it is naturally springy and breathable. The coir foam mattress is also easily recyclable.” Few of the main advantages of coir are that it is renewable, biodegradable and naturally cooling, making it highly suitable for India’s warm climate. “Most of the major mattress manufacturing companies in the country like Coirfit, Duroflex, Kurlon, Centuary Mattress and Sleepwell among others manufacture coir mattresses which offer firm support.”

- Natural Latex (Indian Origin): Sharma says, “India is among the top global producers of natural rubber, with key plantations in Kerala and the Northeastern states. However, the use of natural latex in mattresses is still limited to premium and export-focused brands.” Its biggest appeal lies in the combination of pressure relief and breathability features, along with its long product lifespan. However, there are few challenges also associated with it. The cost of production and certification is high. Further, supply consistency and traceability in sourcing latex that complies with international standards is also challenge in India.

- Organic Cotton: Organic cotton, grown without synthetic pesticides or genetically modified seeds, is used by a few premium mattress brands in India, mostly in outer covers and quilting layers. In fact, India is one of the world’s largest producers of organic cotton, but most of it goes abroad to cater to the Western demand. Domestic usage within India remains limited to niche D2C firms such as Morning Owl or Sunday Mattress that target health-conscious urban consumers. The main hurdle is organic cotton is nearly five times more costly than the traditional cotton.

- Rebonded foam with recycled content: Rebonded foam made by shredding and reprocessing scrap PU foam is one of India’s more innovative circular economy practices, especially in the value-conscious hybrid mattress category. Sharma avers, “By using production leftovers, manufacturers reduce landfill waste and lower input costs. It’s often used as a support core in combination with coir, memory foam or latex

- Coir (Coconut Fiber): Coir has been the backbone of India’s natural mattress segment for decades. Mayank Sharma, Business Head – Hospitality, Premium Segment, King Koil-India, says, “The eco-friendly mattress material market is picking up fast in the country and one of the most eco-friendly materials is Coir. Derived from coconuts’ husk, this product is easily available throughout South India, notably in Kerala, Tamil Nadu and Karnataka. Coir is largely utilised in mid-segment mattress models, either individually or integrated with PU foam layers, since it is naturally springy and breathable. The coir foam mattress is also easily recyclable.” Few of the main advantages of coir are that it is renewable, biodegradable and naturally cooling, making it highly suitable for India’s warm climate. “Most of the major mattress manufacturing companies in the country like Coirfit, Duroflex, Kurlon, Centuary Mattress and Sleepwell among others manufacture coir mattresses which offer firm support.”

- Natural Latex (Indian Origin): Sharma says, “India is among the top global producers of natural rubber, with key plantations in Kerala and the Northeastern states. However, the use of natural latex in mattresses is still limited to premium and export-focused brands.” Its biggest appeal lies in the combination of pressure relief and breathability features, along with its long product lifespan. However, there are few challenges also associated with it. The cost of production and certification is high. Further, supply consistency and traceability in sourcing latex that complies with international standards is also challenge in India.

- Organic Cotton: Organic cotton, grown without synthetic pesticides or genetically modified seeds, is used by a few premium mattress brands in India, mostly in outer covers and quilting layers. In fact, India is one of the world’s largest producers of organic cotton, but most of it goes abroad to cater to the Western demand. Domestic usage within India remains limited to niche D2C firms such as Morning Owl or Sunday Mattress that target health-conscious urban consumers. The main hurdle is organic cotton is nearly five times more costly than the traditional cotton.

- Rebonded foam with recycled content: Rebonded foam made by shredding and reprocessing scrap PU foam is one of India’s more innovative circular economy practices, especially in the value-conscious hybrid mattress category. Sharma avers, “By using production leftovers, manufacturers reduce landfill waste and lower input costs. It’s often used as a support core in combination with coir, memory foam or latex top layers.” Its major advantage is that it is cost-effective. However, the major issues are inconsistencies in quality and the absence of any standard safety certifications. This puts a question on its credibility.

- Bamboo Charcoal Foam: At present, this material is not much popular in India and is used by some niche and premium players only. The foam contains activated charcoal from bamboo, providing antibacterial, odor-absorbing and moisture-control properties. Despite its advantages, bamboo charcoal foam faces certain challenges. The production technology is largely imported, making it expensive and less adaptable for mass manufacturing. There’s also limited domestic expertise in blending bio-based infusions with memory or PU foams without compromising the performance. For now, it’s being explored in India more as a differentiation tool than a mainstream eco-solution.

Many brands in the country are now designing mattresses using green-friendly materials and advanced technologies to ensure quality sleep. At present, Customers may find such mattress costly but the benefits of such mattresses offset its cost as they are not only environment-friendly but also comfortable, breathable and enhance the overall sleep experience.

Circular economy models in mattress production

Apart from adopting eco-friendly materials, opting for circular economy models in mattress production is also extremely important for achieving sustainability. Traditionally, mattress disposal is a big environmental challenge. Every year, millions of mattresses end up in landfill and this leads to pollution and wastage of valuable resources. That said, the future lies in circular economy models, where products are designed for reuse, recycling or safe biodegradation.

- Take-back and recycling programs: Global brands such IKEA and Avocado have been able to start profitable mattress recycling programs where customers are allowed to return used mattresses, which are disassembled and reused in new products or disposed off in an eco-friendly manner.

- Modular mattress designs: Zipped mattress designs with interchangeable layers and separable materials make it simpler to repair and recycle. European companies such as Kipli and Hilding Anders are investing in this strategy.

- Closed-loop manufacturing: Many manufacturers are looking at zero-waste manufacturing, such as reusing manufacturing waste, adopting water-based adhesives, and adopting renewable energy in factory operations. There are a number of other eco-friendly manufacturing processes that can be embraced such as energy-saving production lines using solar or wind energy, waterless dyeing which saves resource and waste-to-energy systems where the waste of manufacturing is turned into fuel. These efforts not only save the planet but also enhance brand value, customer loyalty and sustain Environmental, Social, Governance (ESG) goals.

- Recyclable materials: Use of mono-material components reduces the downstream sorting troubles. So, manufacturers are working towards this too.

- Zero-waste facilities: Certain manufacturers are also reusing the production waste or turning it into carpet underlay, insulation or fuel briquettes.

Challenges for the Indian market

When we talk about India, then despite being one of the world’s fastest-growing mattress markets, India’s adoption of the eco-friendly practices remains limited. This is mainly because of reasons like

- Price sensitivity: People generally think that eco-friendly-materials are costly.

- Low consumer awareness: Indian still do not consider sustainability as an important factor before making a buying decision.

- Supply chain issues: Limited domestic sourcing of certified materials.

- Lack of policy incentives: There is lack of Extended Producer Responsibility (EPR) regulation unlike in Europe or U.S. for sustainable manufacturing.

- Limited recycling ecosystem: Most used mattresses still occupy large landfill spaces.

Even with these challenges, India has a huge potential to transform into a sustainable manufacturing base, particularly with world buyers seeking to diversify sourcing away from China. Further, growing urban incomes, health consciousness and export aspirations may power a green revolution in India’s mattress industry. Here, it is to be noted that organisations like Indian Sleep Products Federation (ISPF) are also doing their bit in promoting sustainability in the mattress manufacturing segment.

Role of ISPF in catalysing sustainable growth

ISPF plays a critical role in shaping the future of sustainable mattress manufacturing in India. Srinivasan Sundaerasan, Secretary, ISPF, avers, “The level of awareness is extremely low for sustainability in the mattress industry. Therefore, one of the biggest goals of ISPF is to create awareness for green material usage and processes in the mattress industry to help foster sustainability. We inform customers regarding standards and certification for environment-friendly products, educate consumers and retailers about the importance of green mattresses and organise forums such as ‘World of Sleep’ at HGH India emphasising sustainability breakthroughs to make manufacturers, suppliers and materials innovators collaborate.”

Strategic benefits for mattress manufacturers

Despite the challenges, mattress manufacturers are touted to gain if they go the eco-friendly way as the future of the mattress industry lies in sustainable innovation. By investing in sustainability, manufacturers can earn the customer trust, increase brand loyalty and reduce costs. This is because from bamboo fabrics to circular economy designs, green mattresses are no longer a niche. They are quickly becoming the new normal. Mattress manufacturers who move now in this direction can gain a good market position. That said, while regulations in the world become more stringent and India starts waking up to the sustainability imperative, themoment is perfect for the courageous leaderships in India as well as abroad.

The Indian landscape: The eco-friendly shift is round the corner

India’s mattress industry is huge. Yet e theco-conscious manufacturing is still in its infancy. As per RedSeer Analysis, 2024, “Only 1 in 50 branded mattresses in India are certified with global eco-labels.” So, there are good opportunities for growth. The healthcare and hospitality industries in India are now starting to require low-VOC, antimicrobial and biodegradable materials based on ESG reporting needs.

Industry in 5 Minutes

The mattress market is experiencing a green revolution and eco-friendly mattress materials are transforming the sleep industry globally. Today’s consumers are not only concerned about comfort but also want to know as to what goes into their mattress, where it is produced and what happens to it when its life ends. Overall, customers of today want to ensure that their mattress does not contribute to the environmental pollution. So, the movement towards greener products is gaining momentum.

As for the Indian mattress industry, the moment is today. From factory modernisation to taking on circular design and material innovation, there are distinct, doable avenues to develop environmentally sound products that deliver. While other global brands test carbon-negative and totally circular designs, Indian industry can leapfrog into green leadership by tapping local materials such as coir, latex and organic cotton, and conforming to international certification norms. For Indian manufacturers, there lies dual opportunity in serving the growing local eco-segment and exporting to sustainability-driven markets. This capacity building in certified materials, transparency and circular design now will lay the foundation for long-term competitiveness in a rapidly greening global market.

Simply put, eco-friendly mattress products are no longer an experiment, they’re a proven and profitable way ahead. From closed-loop designs and natural materials to factory breakthroughs and global regulatory compliance, green production is the future of the mattress business. What more? Sustainability is not only good for the planet, but also for long-term profitability, risk mitigation and brand reputation and the brands that adopt sustainability now will only prosper in the future.

Indian mattress manufacturers in India can do the following things to move on the path of sustainability

- Conduct an audit of existing materials and processes to determine their environmental footprint.

- Research about certified suppliers of organic, renewable and recyclable materials.

- Educate R&D teams on designing modular and recyclable products.

- Work with green startups for material and process innovations.

- Tell and show sustainability efforts through labeling and certifications

- Meet with policymakers to push sector-specific reforms and incentives.

- Design mid-priced eco-friendly products. For example, they can blend recycled foam, coir and cotton to appeal to India’s new eco-conscious consumer.

CEO Corner

Nirbhay Gupta, CEO of Coirfit Mattress

Nirbhay Gupta, CEO of Coirfit Mattress explains, “About 1,300 tons of cotton fibres and coir (coconut fibre) are extracted from discarded mattresses annually so we strongly believe that the recycling of coir mattresses can contribute to a sustainable environment. Recycling coir mattresses can be effectively carried out by implementing proper collection and recycling processes.