THE MATTRESS DICTIONARY

The question is how we can ensure the consumer is well informed. As they say, educating oneself to educate others is the best formula. In this article, we attempt to draw readers’ attention through the mattress dictionary to the information they will already know as part of their day-to-day work but would not have cared to store in memory in any structured way.

Educating the consumer about mattress materials and how they are made is half the battle won in terms of sales. “It’s more than sales. Since we are a physical store, we do not want our customers to come back with problems,” says Nagaraj N, a mattress retailer in Magadi. “It is better to educate them at the first instance and that it makes for good salesmanship is a bonus for us,” he adds.

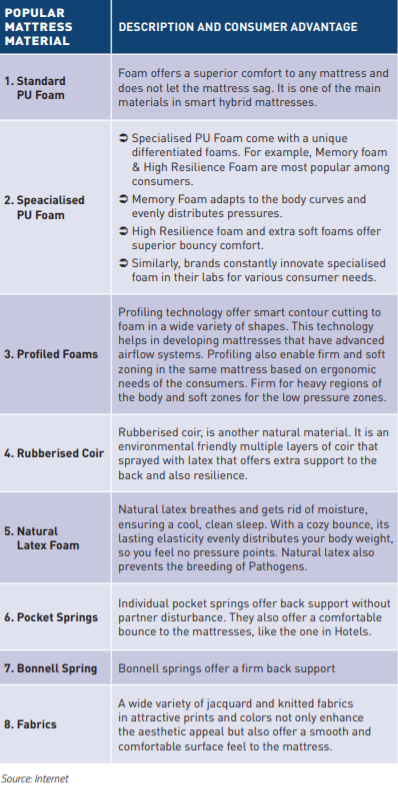

THE MATTRESS MATERIALS

|| Foam

Foam has been around for a while as a mattress material. It is soft and is able to absorb body movement which, in turn, helps in temperature regulation and pressure point relief. These are important in providing firm support to the spine and sleeping comfort.

Some common types of foam include Standard PU Foam, and Specialised PU Foam, (Memory Foam & High Resilience Foam) which are most popular among consumers.

Memory Foam is a specialized PU Foam, that NASA engineers used to make airplane cushions for astronauts. The popularity of this gave rise to a plethora of foam-based mattresses. Another popular material is Gel Memory Foam.

In order to understand the range of Memory Foam Mattress, we should know what they are. These mattresses are made of lush layers of Memory Foam material that has the ability to conform to a shape. It gets its name, Memory Foam, because of the nature of changing its shape to the contour of the body.

The gel memory foam is a newer range that uses a technology called Phase Changing Material (PCM). In the case of a PCM such as Gel Memory Foam, when the temperature rises, it warms up absorbing heat during this phase change and eventually melting, causing the surroundings to cool. The reverse occurs when the temperature falls. It freezes and releases heat, warming up the environment. Thus, it adds to the shape-conforming nature of the Memory Foam.

Looking at the two extremes of hard to soft mattresses, foam layers work in tandem to relieve pressure points from joints and balance body temperature. These layers conform to the body shape and absorb movement so the sleep is undisturbed.

The Profiled Foams enable firm and soft zoning in the mattress and also enhance air circulation for freshness

|| Rubberised Coir

Rubberised Coir is an advanced version of coir which is made from coconut fibre and processed Natural Latex rubber. Thus lending it more flexibility, finesse, and durability and enhancing its even firmness feel.

|| Natural Latex Foam

Natural latex breathes and gets rid of moisture, ensuring a cool, clean sleep. Moulded foaming technology allows the mattress layers or pillows to take the shape of a predefined mould for the best ergonomic advantage. This technology enables the foam to adapt to the body contours with an intelligent movement response, as one changes position while sleeping. Moulding offers a protective skin around the structure offers the protection to the foam, without compromising on breathability and hygiene.

|| Innerspring Mattress

Innerspring mattresses have evolved from the old world but have taken the modern world by storm. It owes its fandom to its longevity and comfort. Inner Spring mattresses, as the name suggests, are made of steel coil springs crafted into open coils (springs) or individually wrapped coils which are popularly called pocketed coils or springs. These spring components establish firm support at the base of the mattress and are then filled appropriately to offer cushion and comfort.

Because of the dynamic nature of the steel coils, one has to understand that the number of coils doesn’t always amount to the same level of comfort from one mattress to the other but the density of springs plays a role in reducing motion transfer and offering support.

Each manufacturer uses different designs and support techniques to achieve the ultimate result. He may often include layers of polyurethane foam and other fillings inside the mattress. However, more luxurious innerspring mattresses will use other kinds of foam, including memory foam, gel memory foam and latex materials.

Pocket Springs and Bonnell Springs are the other two varieties of springs used in mattress manufacturing. While Bonnell Springs offer firm support, Pocket Spring bases ensure no partner disturbance due to their unique pocket designs.

Another variation of Innerspring Mattresses is the BoxSpring mattress, widely used in international markets. A BoxSpring often has spiked coils that are stapled to the bottom to a flat wooden frame over which a wire mesh is placed. On top of this foundation, a thin layer of upholstery is applied. This frame is then inserted into a pre-sewn cover that encases the top and sides of the unit. A border fabric that matches the mattress exterior is applied to the sides, and a dust cover is added to the face.

|| Hybrid Mattresses

The hybrid mattress is the combination of two or more materials that go into the manufacturing of a mattress. For example, a mattress with a spring coil and memory foam. The coils offer support, while memory foam layers conform to posture and comfort. Cotton fabric blends are added to protect the bed. You get the best of both mattress types above in the hybrid, plus personalized materials that are going to work together to help you get a good night’s sleep.

|| Wool

Can be found in some mattresses for extra padding and temperature regulation. Wool is a breathable material used both inside and outside of the mattress. It has unique temperature-regulating properties Mattresses are presently made of many materials, both natural and synthetic. The innerspring, helical, and Box Spring components are made from wire; the BoxSpring wire is typical of a heavier gauge than that used in the innerspring. The insulator consists of semi-rigid netting or wire mesh, and the cushioning layers can comprise a number of differences that are crucial in a mattress.

Wool is a great natural insulator and its moisture-wicking properties are a boon in the summer months to wick sweat and heat through the layers of wool fibres keeping you cool when it’s warm.

In the cold winter months, the layers trap warm air in and help to keep you warm. This makes it a perfect mattress filler as keeping a comfortable body temperature ensures a good night’s sleep. It is sustainable, recyclable and biodegradable.

Wool is one of the biggest antiallergy agents. Wool traps and holds onto dust particles and absorbs air pollutants making it a natural air purifier. This is great for those who suffer from allergies or hay fever in the summer months and helps to create the healthiest sleeping surface possible.

EACH MANUFACTURER USES DIFFERENT DESIGNS AND SUPPORT TECHNIQUES TO ACHIEVE THE ULTIMATE RESULT

COVER MATERIALS CAN RANGE FROM POLYESTER TO COTTON OR STRETCH KNIT, EACH ONE DESIGNED TO BE SOFT AND BREATHABLE.

HOW THE MATTRESSES ARE BUILT

Mattresses are presently made of many materials, both natural and synthetic. The innerspring, helical, and BoxSpring components are made from wire; the BoxSpring wire is typical of a heavier gauge than that used in the innerspring. The insulator consists of semi-rigid netting or wire mesh, and the cushioning layers can comprise a number of different materials including natural fibre, polyurethane foam, and polyester. The flanges are made of fabric, and the hog rings are of metal. The top, bottom, and side panels consist of a durable fabric cover quilted over a backing of foam or fibre, and the binding tape that holds the ticking together is made of heavy-duty, fibrous, synthetic material.

The underlying BoxSpring may consist of either a wooden frame with slats or metal coils similar to those used in the mattress itself. The BoxSpring may be upholstered, but, even if it is not, it always receives a fabric covering.

MATTRESS COVER FABRICS AND QUILTING MATERIALS

A wide range of woven, & knitted fabrics in various colourful prints and attractive designs are the outermost material that not only protects the mattress but also offers smooth touch and enhances the aesthetic appeal.

The fabric is mostly quilted using layers of specialized soft quilting foams for a superior loft, which enhances the comfort level as one sleeps. The use of specialised foams in quilting lends the top surface a plush comfort.

The quilting pattern prevents the mattress cover from slipping or creeping over the layers of quilting, in addition to enhancing the aesthetic and comfort appeal of a mattress.

Cover materials can also range from polyester to cotton or stretch knit, each one specifically designed to be soft and breathable.

|| Edge Supports

When you wake up and get ready for the day, edge support materials are important — especially if you prefer to put your shoes on while sitting at the edge of the bed! These materials range from thick metal rods to foam wall encasements. The more edge support you have, the better the comfort for sleeping and sitting!

ADHESIVES AND FIRE RETARDANTS

Used in mattresses to bond layers, materials and seams together for the perfect fit. Quilting is often used in combination with adhesives to further strengthen the bond between layers.

The mattress will also have Flame retardants. Flame retardants are chemicals used on mattresses and furniture in order to slow down the spread of flames. These chemicals will make the burning property as low as possible to keep the damage under control.

THE MANUFACTURING PROCESS

|| Building Mattress Layers

- For innerspring mattresses, springs are arranged on top of an insulator base to create a wire mesh and then a layer of the insulator is applied as a top layer. In the case of Pocket Springs, The pockets are stitched and aligned together in a way, which ensures no partner disturbance.

- Next, cushioning layers are applied that will determine the feel and comfort of the final product.

- A decorative cover is prepared on a giant quilting machine, which controls a multitude of needles that stitch the cover to a layer of backing material.

- The stitching chosen serves both useful and ornamental purposes, as it must prevent the mattress cover from slipping or creeping over the layers of cushioning in addition to creating a visually pleasing exterior.

- Once the fabric is quilted, it is cut into panels that will fit the top and bottom of the mattress. The side panels are often cut from this same composite or made separately on a border machine. If side handles or vents are to be added, they are attached to the side panels before they are applied to the mattress.

- Specific to innerspring mattresses: Specially modified sewing machines are used to attach the flanges to the top and bottom panels, and the hog rings are stapled to the flanges. Everything is now ready for the closing operation, during which the hog rings will be secured to the innerspring unit.

|| Completing the mattress

- Tape edge operators manually feed the top, bottom, and side panels and a heavy-duty binding tape into the sewing machine as it moves around the mattress. As this combination of materials is fed into the machine, the operators use their skill to feed the proper amount of each material into the machine to produce a professionally tailored product.

- Some of the highest quality mattresses may also feature a pillowtop, an additional comfort layer filled with extra comfort layers and attached to the top and side panels of the mattress for a more luxurious feel and appearance. Prequilted, the pillowtop is taped to the mattress top.

|| Inspection, labelling, and packing

- Once the units are complete, they are inspected for quality. If everything is in order, they are labelled with the content and the contingent “Do not remove” tag, required by law to assure the consumer that the contents are properly represented in the labelling.

- The finished product is then transported to the packing area. Here it is inserted by hand or by automated machinery into protective plastic or paper covers. Additional information about the warranty, safety, and care of the product is also included in the packaging.

|| Quality Control

During the manufacturing phase, most quality control procedures are carried out by sight. Further, each batch of mattresses is tested in the Lab to conform to the standard specifications for each model. This is to ensure that there is ZERO defect on the products produced. The majority of manufacturers implement inspections at critical points in the

production process: after receiving the innerspring, before the closing, and before packing.

A mattress may not appear too complex at first glance but has a lot that goes into it, literally. If one knows a mattress, then good comfortable sleep is never a dream.